Metal tiles are a roofing material made of steel coated with zinc and polymer paints, manufactured in the form of sheets. The metal tile has a profile that allows sheets to be joined in length and width.

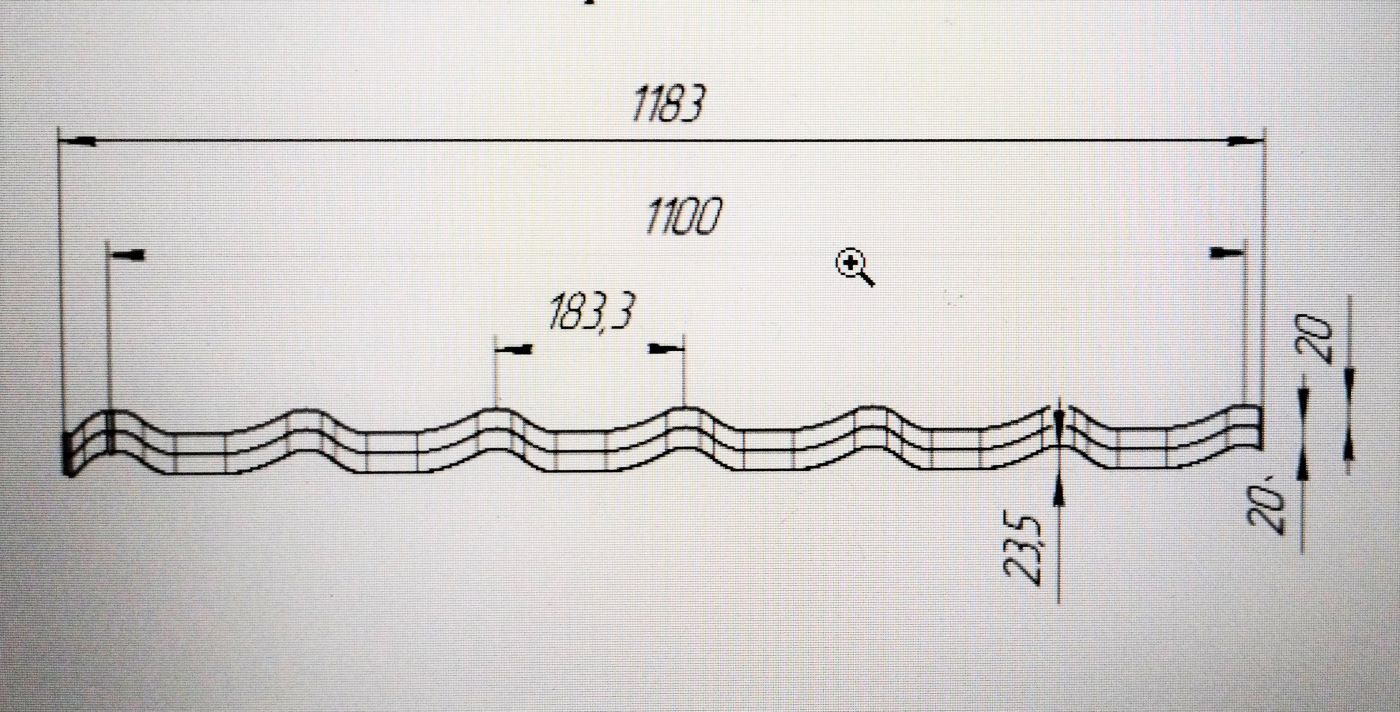

Most popular profile view

For this profile, the manufacturer gives the following dimensions (in mm):

1183mm – full sheet width

1100mm – useful sheet width

183.3 mm – profile pitch

23.5 mm – profile depth

20 mm step height

There is also the length of the sheet and the length of the step. For this profile, the step length is 350mm.

The geometric dimensions of the sheets should ensure that there is no leakage of water between the sheets when they are connected with roofing screws without the use of various seals and sealants. For this purpose, GOST R 58753-2018 established requirements for the geometric dimensions of sheets.

The tolerance for the useful and full width of the sheet is plus 5 mm, that is, the sheet is considered to be of high quality if its width is in the range from 1183mm to 1188mm. (Useful – from 1100 to 1105mm). If you calculate the width of the roof using a sheathing of 15 sheets, it will be 1100×14+1183=16583mm – the minimum size, 1105×14+1188=16658mm – the maximum size. The difference is 75 mm. Metal tiles come to order in a pack of one size, and it happened that the size was 1195mm. (The roof was made of 10 sheets).

In such cases, according to the size indicated in the drawings, the sheathing is made 2-3 cm wider than indicated in the drawings, and the metal tiles are cut to the required size. Why is this bad?

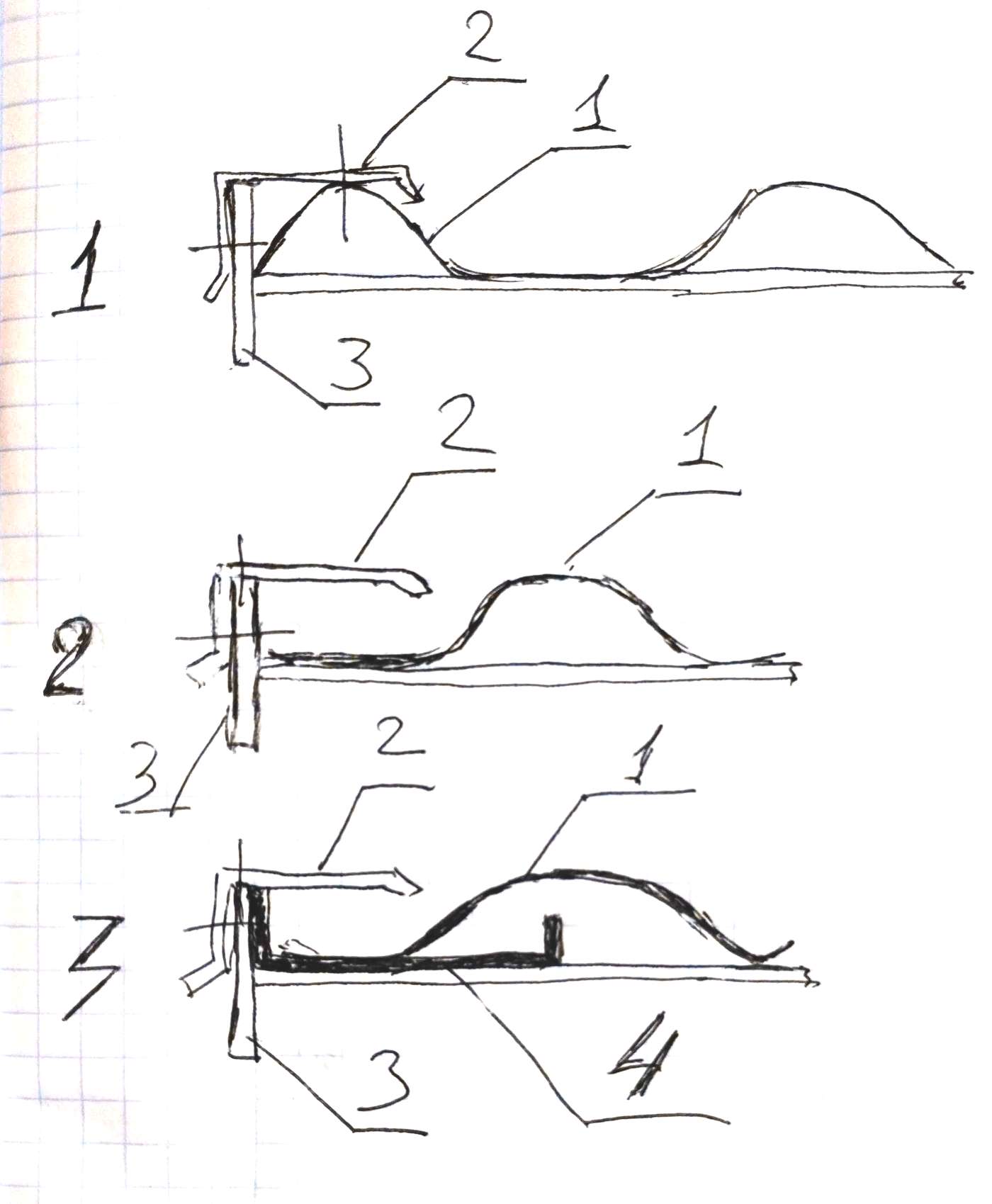

The top of the wave is at the edge of the sheet, and it is cut off. In this case, the eaves strip is installed so that water flows under it and flows under the edge of the metal tile (since the top of the wave is cut off). In order to prevent leakage, it is necessary to install a valley.

The valley is made of metal, it is not visible, so it can be of any color.

1- Metal tiles

2- End strip

3- End board

4- Endova

In the next article we will look at tolerances for other sizes of metal tiles.